The call for better cleaning

The Pain of Corrosion Pits.

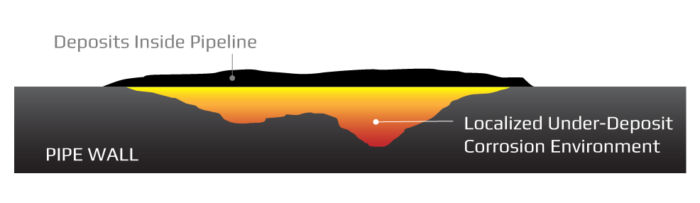

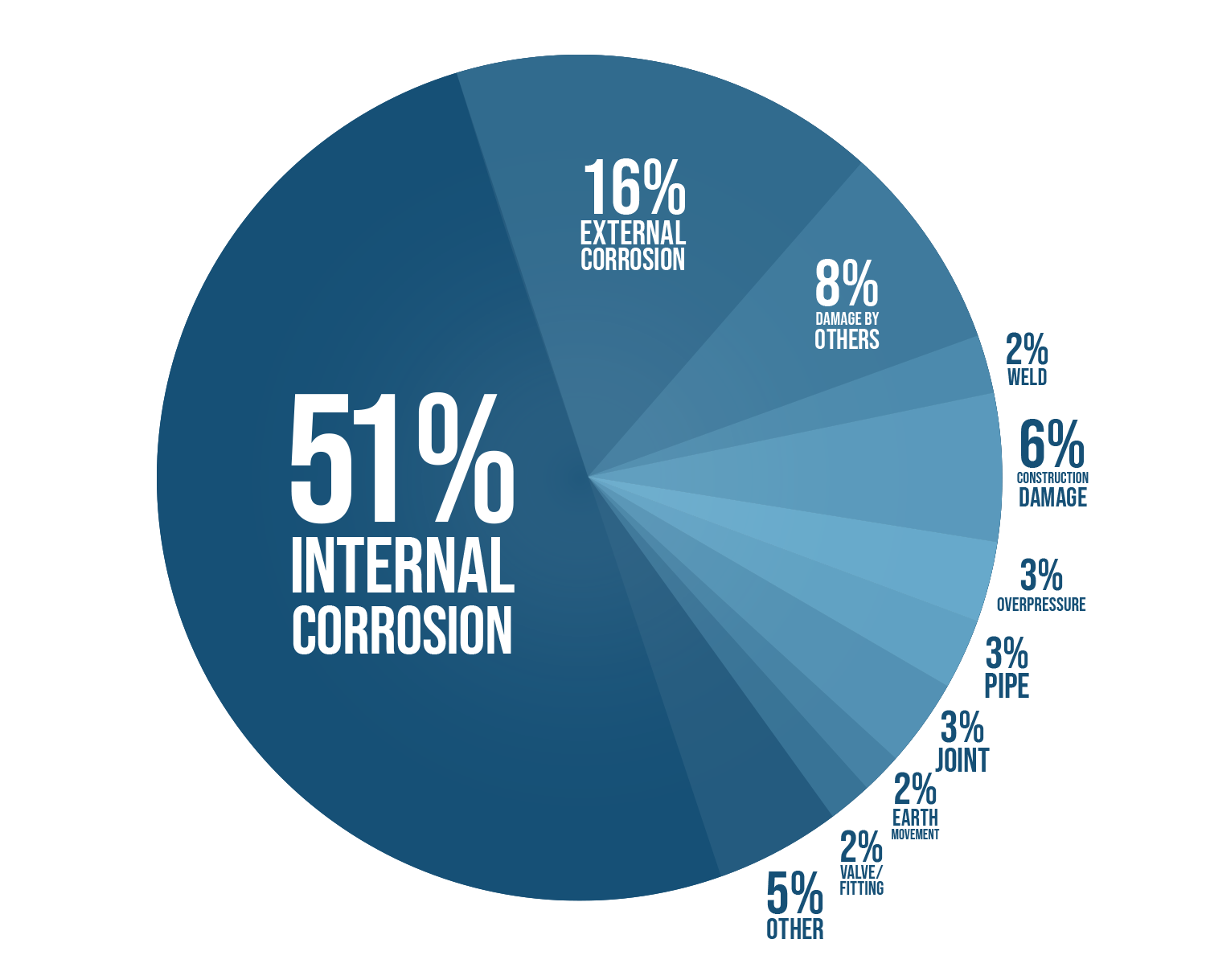

Widespread corrosion pitting in existing pipeline infrastructure is a major concern. In fact, internal corrosion causes 51% of all upstream multiphase pipeline failures, with pits being caused by under-deposit corrosion. The pits are commonly deep and narrow, with complex and variable geometry that can make them extremely challenging to clean. This pitting corrosion can cause pinhole leaks that are difficult to detect and can leak for a long time before failure is identified.

And the problem just builds on itself. Without effective cleaning, pits collect further deposits and the corrosion continues to deepen through the pipe wall. And these deposits prevent corrosion inhibitor chemicals from working at the bottom of the pits where they are needed most. The ultimate result of longtime corrosion and undetected leaks is significant environmental damage and financial penalties.

Learn about how Fiberbuilt’s Corrosion Pit Cleaning Pigs address these challenges.

[1] Alberta Energy Regulator (AER), “Report 2013-B: Pipeline Performance in Alberta, 1990-2012”, August 2013, Available December 2016 at: https://www.aer.ca/documents/reports/R2013-B.pdf

Shortcomings of Current Cleaning & Scouring

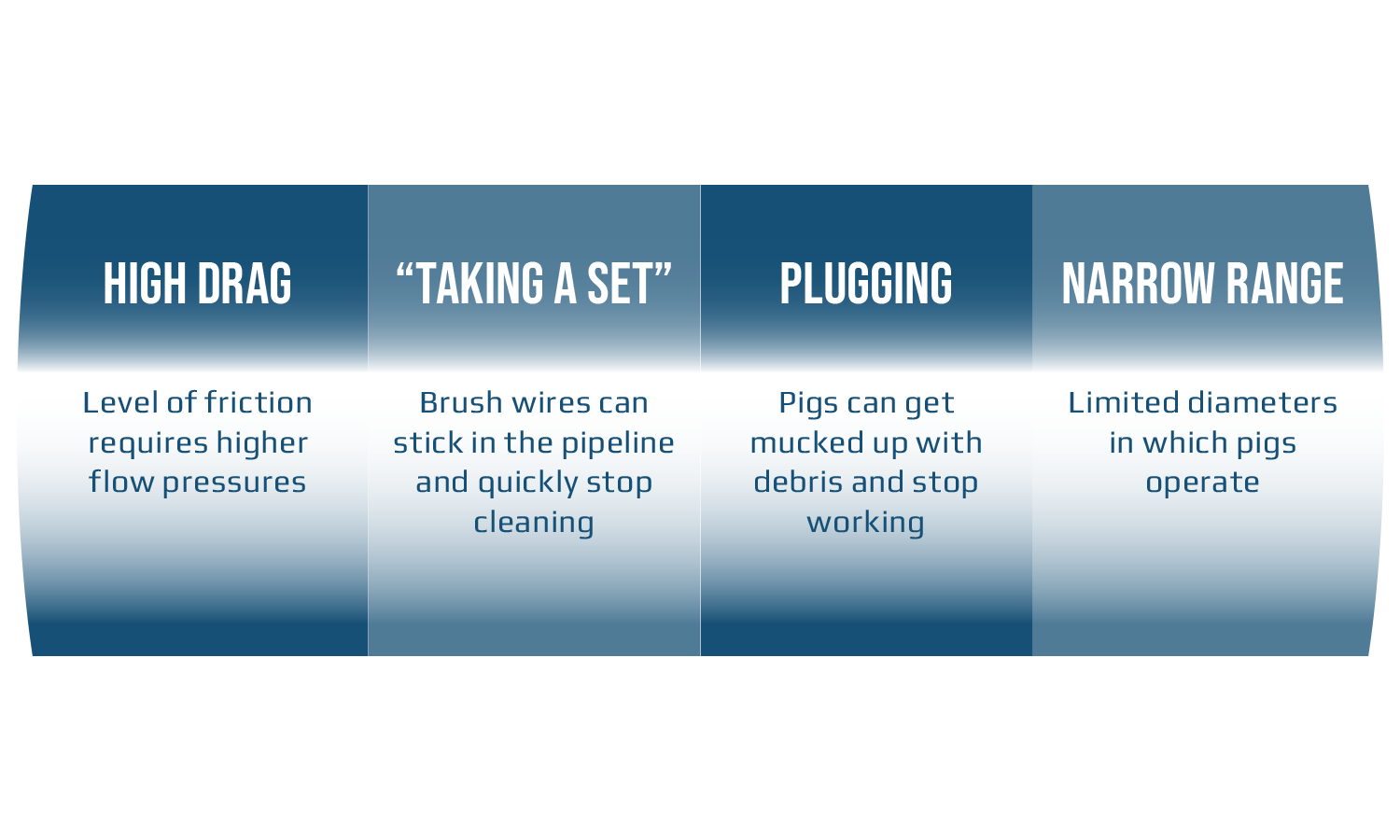

Today, it’s common practice to deploy brush pigs to clean and scour debris from pipe walls. The problem is that typical brushes are not designed and constructed for this application. Insufficient materials and poorly conceived brush designs result in brushes that under-perform. Learn about how Fiberbuilt’s radial Brush Pigs address these challenges. Learn MoreUnpiggable and difficult-to-pig pipelines

What Could Be Worse Than a Stuck Pig?

There is a variety of structural pipeline anomalies that can dramatically affect the flow of pigs and their abilities to clean within pipelines. Circumferential welds can cause pig seals to hang up and cause pig to stop. Dents in pipe walls can stop the stiff, heavy urethane seals in ordinary pigs as they may not be able to deform to pass the dented section. And complex pipeline geometries can cause difficulties in achieving pig success. This all leads to a need for pigs with the flexibility to perform simple cleaning tasks in pipelines with known ID anomalies and geometry problems. Learn about how Fiberbuilt’s Multi-Diameter Pigs address these challenges.