Cleaning Pigs

Fiberbuilt’s cleaning pigs provide the industry’s best cleaning and have a flexible design that gets through just about anything.

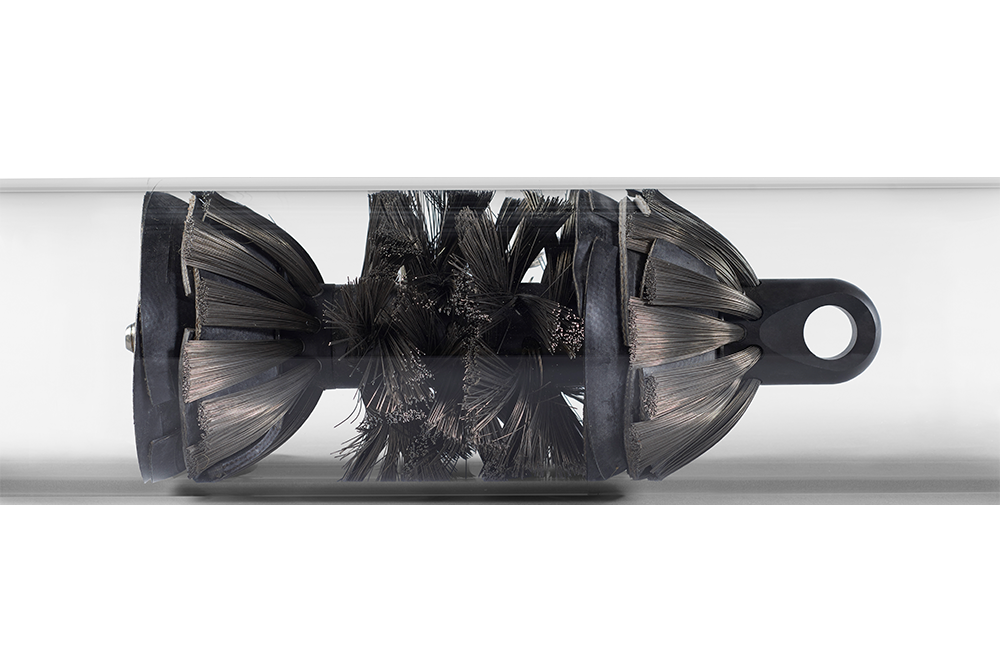

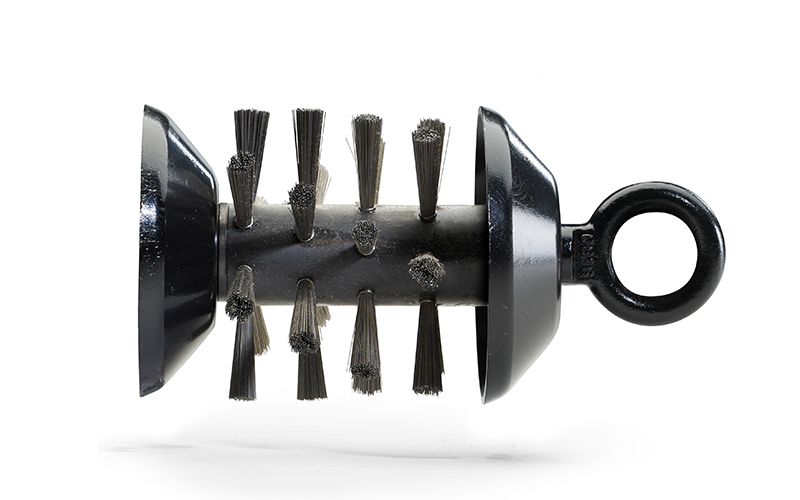

CORROSION PIT CLEANING PIGS

Fiberbuilt’s Pit Cleaning Pig uses Corrosion Killer technology, made from thousands of ultra-high strength tempered spring steel wires, to dig out material with a forward reaching and penetrating action into the full depth of corrosion pits. This action removes up to 80% more volume from the pits than the industry’s existing brush pigs.

- When deployed in a successive pigging program, the depth and volume of pit cleaning has been proven to improve with each pass

- The more thorough pit cleaning possible with the Fiberbuilt corrosion pit cleaning pig allows the entire corrosion mitigation program to be more effective

- Maximizes the effect of chemical cleaning and corrosion inhibition applications

- Available with patented Fiberbuilt Composite Seals or a more traditional urethane cup type seal in 3”, 4”, 6” and 8” configurations

- Custom sizes and designs available

Corrosion Pit Cleaning Pig with Fiberbuilt Composite Seal

For more difficult-to-pig pipelines, this patent-pending seal allows for easy pigging through pipeline diameter changes, dented sections, and pipelines with low flow rates.

Corrosion Pit Cleaning Pig with Urethane Seal

The urethane cup seal can be used as a cost-effective option for easily piggable lines with higher operating flow rates and differential pressures.

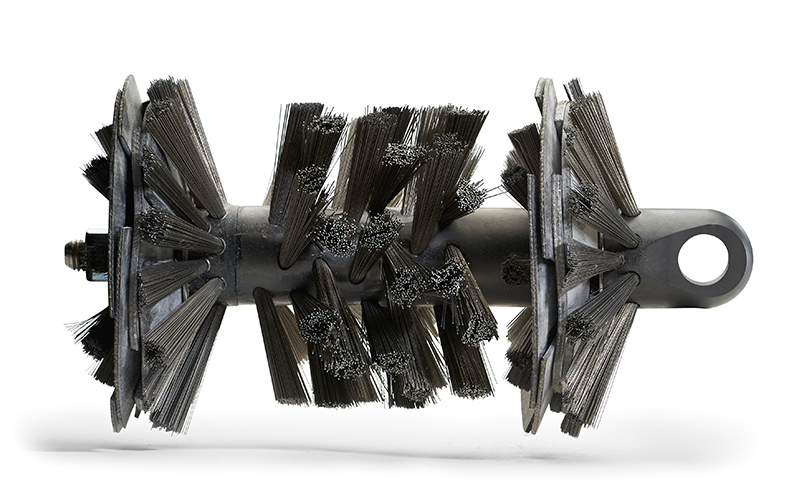

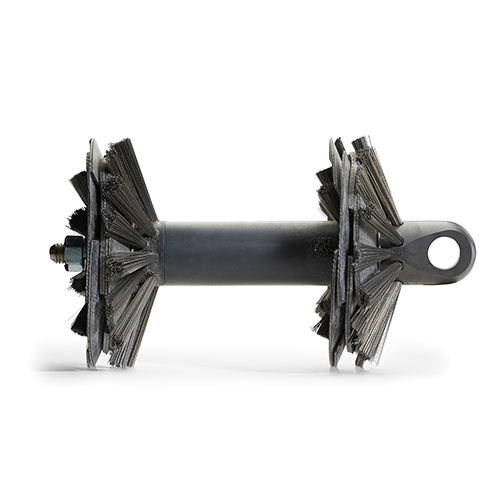

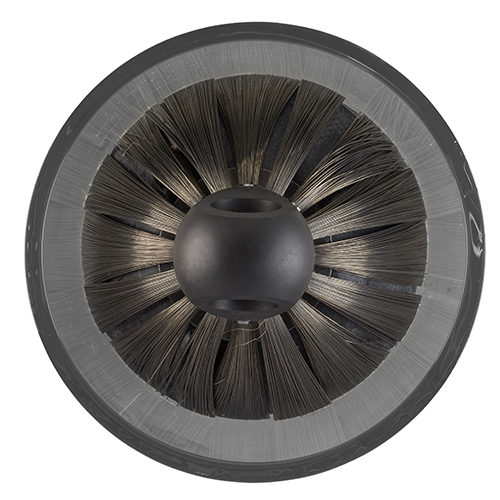

BRUSH PIGS

Fiberbuilt Brush Pigs utilize smart tool brush technology to provide the pinnacle in aggressive cleaning and performance. Built with patented Fiberbuilt pencil brush technology, these are the highest grade brush pigs available in the industry.

- Available with the patented Fiberbuilt Composite Seal technology and a more traditional urethane cup type seal in 3”, 4”, 6” and 8” configurations

- Custom sizes and designs available

Radial Brush Pig with Fiberbuilt Composite Seal

For more difficult-to-pig pipelines, this patent-pending seal allows for easy pigging through pipeline diameter changes, dented sections, and pipelines with low flow rates.

Radial Brush Pig with Urethane Seal

The urethane cup seal can be used as a cost-effective option for easily piggable lines with higher operating flow rates and differential pressures.

PURGING PIGS

The Fiberbuilt Purging Pig’s composite seals allow purging & dewatering to be completed at lower operating pressure, easily flowing through just about any feature that make lines difficult to pig.

- The composite seal allows for the purging & de-watering pigs to be deployed and effectively operated in complex pipeline geometries with schedule changes, diameter changes, or other pipeline ID anomalies that may otherwise restrict regular pigging operations

- Low-differential pressure drag seals allow for purging & dewatering to be completed at lower operating pressures, simplifying operations and increasing safety

- Available in 3”, 4”, 6” and 8” configurations

- Custom sizes and designs available

Purging Pig with Fiberbuilt Composite Seal

The patented flexible brush/diaphragm/brush seal design allows for low differential pressure pigging through pipeline diameter changes, dented sections, and pipelines with low flow rates and pressures.