Engineering Services

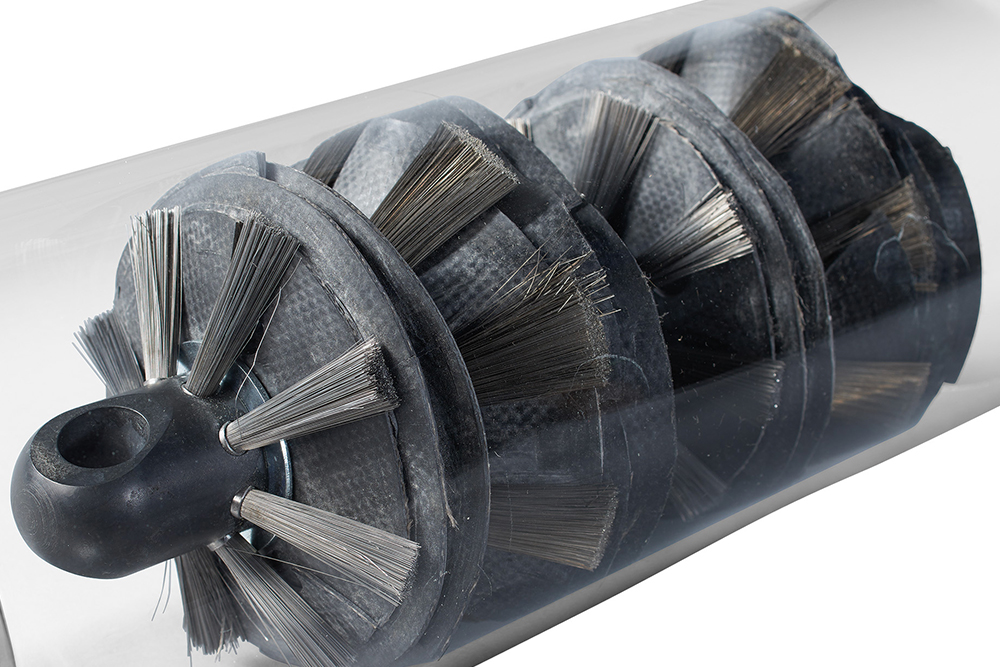

Custom Pig Design.

The extremely flexible Fiberbuilt Composite Seal design, along with the modular architecture of Fiberbuilt’s pigging products, allows for pigs to be rapidly configured for custom applications and pipeline requirements. Pig lengths can be extended, and seals repositioned and duplicated for redundancy or to ensure bridging across a particular pipeline feature that may be difficult to pig. Contact Fiberbuilt today if you require a custom-configured pig and our applications engineers will work to meet your unique pigging requirements.Validation of Complex Pipeline Pigging Applications.

In creating the Fiberbuilt Composite Seal technology, Fiberbuilt has developed a unique testing regime and custom instrumentation to prove pig passage through difficult-to-pig pipeline features of almost any type. If you need to reduce the risk of deploying an unproven pig configuration in a difficult-to-pig pipeline, the engineers at Fiberbuilt’s R&D/test facility can develop a series of above ground pig passage proving tests, designed to replicate the pig passage characteristics through the unique pipeline anomaly as specified.

The data from this low-risk above ground testing can be used to

iteratively design the correct pigging solution for your application

and prove that it will pass through the suspected ID anomalies,

maximizing the probability of a successfully deployed and retrieved

custom pig configuration. Costly delays and the potential for stuck

pigs can be virtually eliminated through comprehensive above

ground pre-run proof testing.